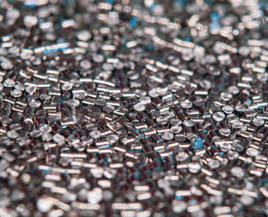

Why Choose

Aluminum?Aluminum die casting produces lightweight parts with superior heat resistance—and more surface finishing options than any other die cast alloys. Its versatility, corrosion resistance, and dimensional stability make it ideal for various applications.- 140+ machines worldwide

- Ranging from 125 tons to 580 tons

- 8kg (17.62lbs) maximum part weight

- Cost-effective

- Lightweight properties

- Enhanced strength and hardness

- Adequate stiffness and strength-to-weight ratio

- Exceptional corrosion resistance

- Excellent finishing characteristics

- Recyclability

- Ease of sterilization

- Heat dissipation

- High operating temperatures

- Superior thermal conductivity

- High electrical conductivity

Performance Metals

Alloy Properties and Applications

A380

A380

A380 is one of the most specified aluminum alloys with a number of significant benefits.

A383 (ADC12)

A383 (ADC12)

If your component is highly intricate, 383 – also known as ADC12 in Asia – is often used as an alternative to A380.

B390

B390

B390 is an aluminum alloy with high hardness and good wear resistance.

A413

A413

A413 is an aluminum alloy with excellent pressure tightness.

413

413

413 is an aluminum-based alloy that is used for die casting parts. 413 Alloy has a higher magnesium content and a lower iron content than A413.

K-Alloy

K-Alloy

K-Alloy is an aluminum, cold chamber die cast alloy that was engineered to protect components against harsh operating environments.

A360

A360

A360 is an aluminum alloy with excellent pressure tightness and fluidity.

How Our Metal Selection Fosters Innovation Through Customization

Our advanced materials allow for more design flexibility, enhancing part quality in every project.

.png&w=268&q=75)